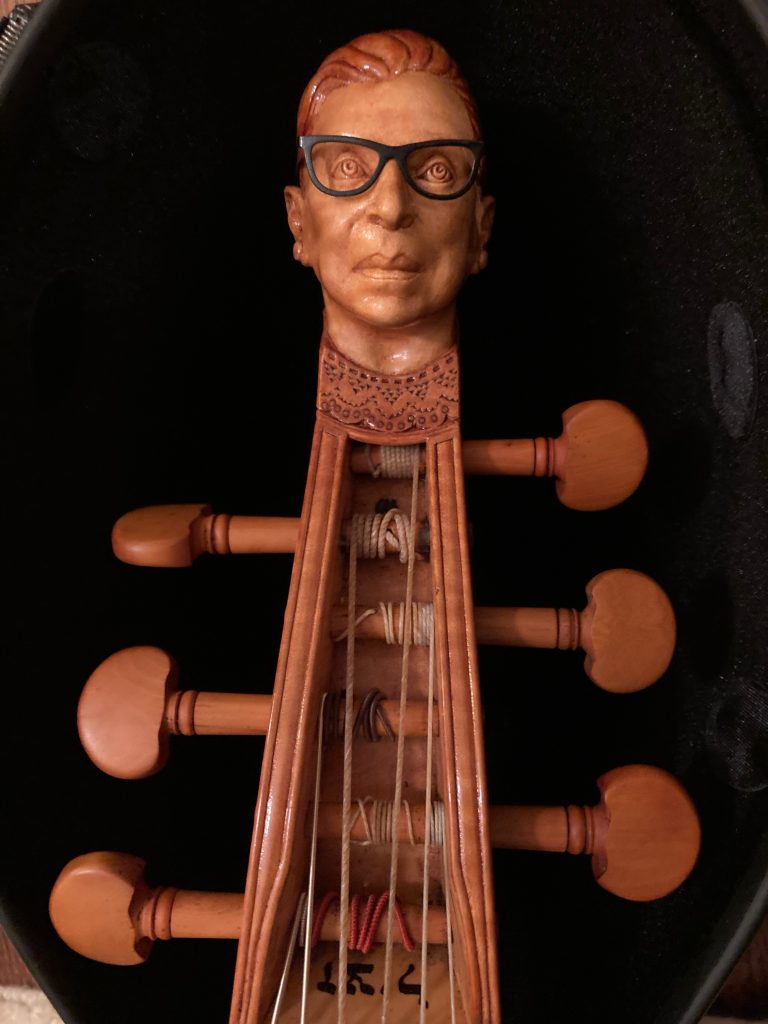

A friend was building a viola da gamba for a client and asked me if I would like to have a go at making tuning pegs for it. I made a few prototypes and delivered the boxwood pegs shown installed in instrument here. They were originally a light yellow color and were darkened using nitric acid.

I did the work on my lathe using a gouge, skew chisel, some stock and custom scrapers, and a bit of sandpaper. Woodturning is a subtractive process and I used a digital caliper to carefully guide the shapes to tolerances of less than 0.1 mm. It’s hard to work at that level of precision on a wood lathe and I didn’t enjoy the process.

When my friend asked me if I wanted to make a set of pegs for a viola, I recast the problem to one of building a precision duplicating and shaping system for my wood lathe.

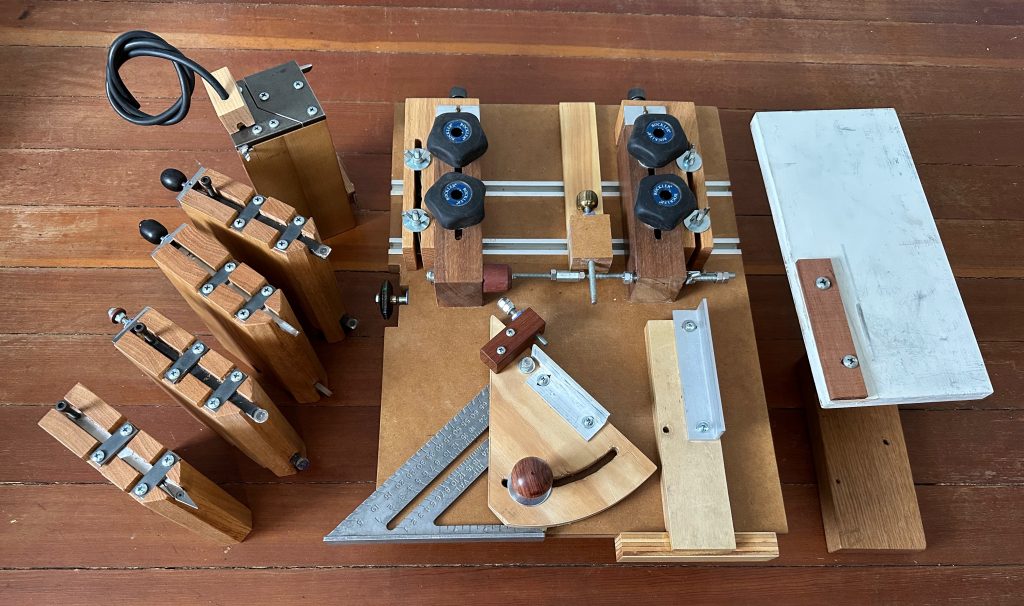

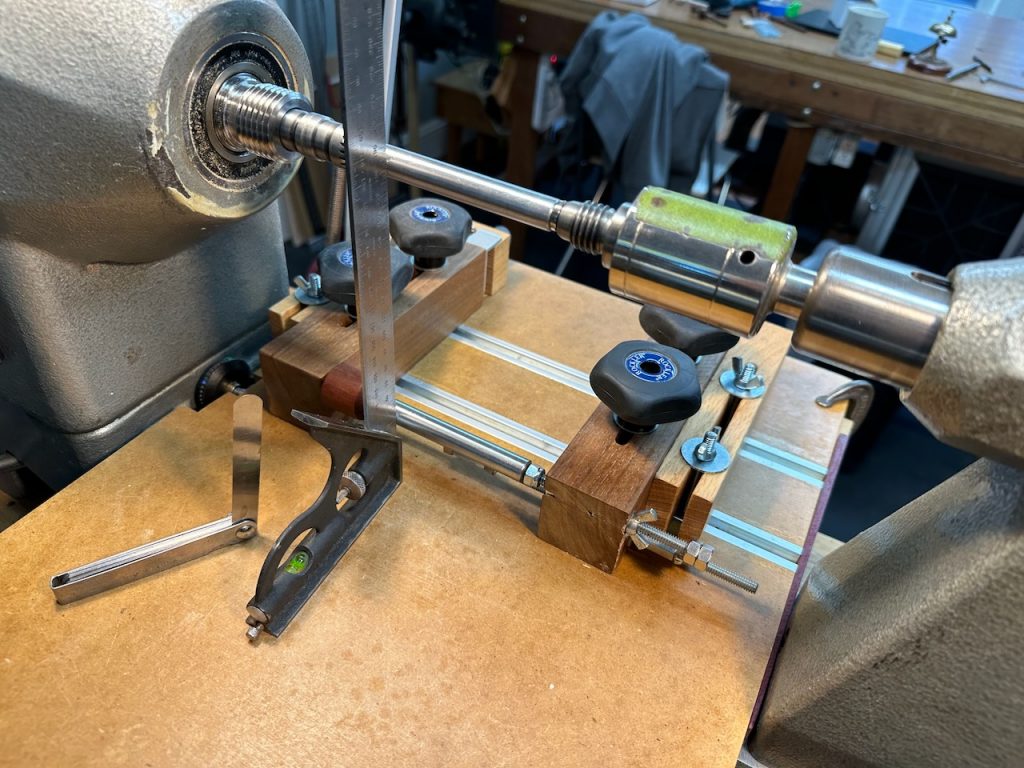

I eventually built a precise system, parts of which are shown here. It works well, but would have been easier to build if I had based it on a small metal lathe.

I built a table that securely sits on top of the lathe bed and is held in place with shims and an alignment screw.

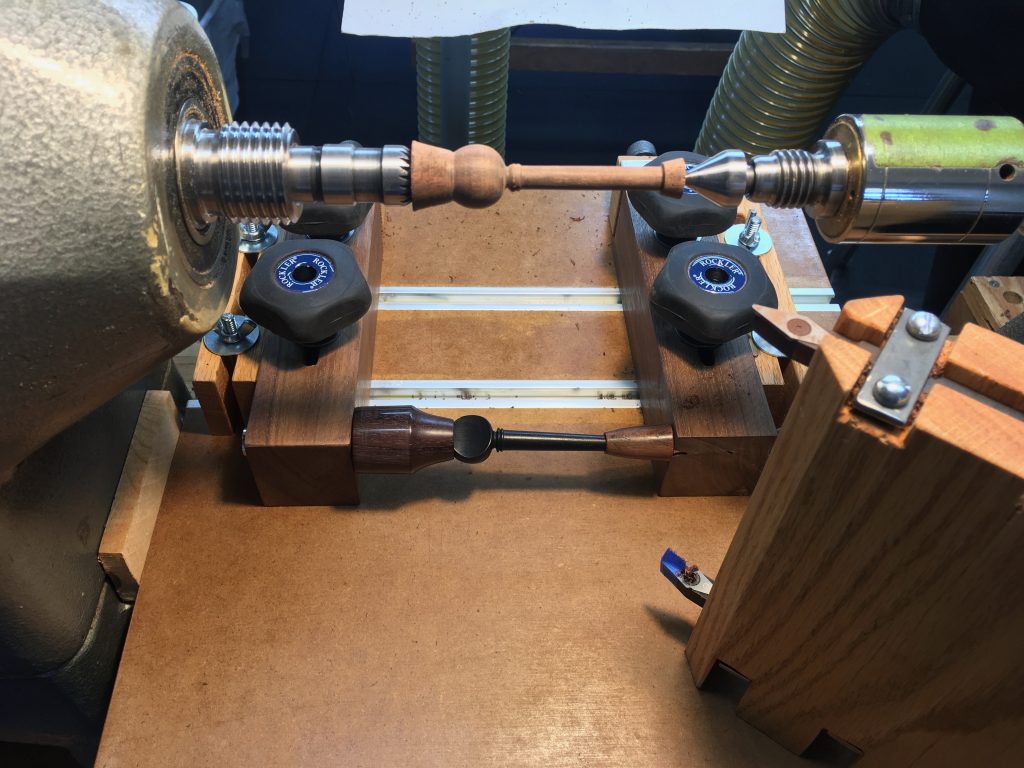

I used the center holders I had originally built for tapering table legs and added a way to precisely move them to align with the lathe spindle.

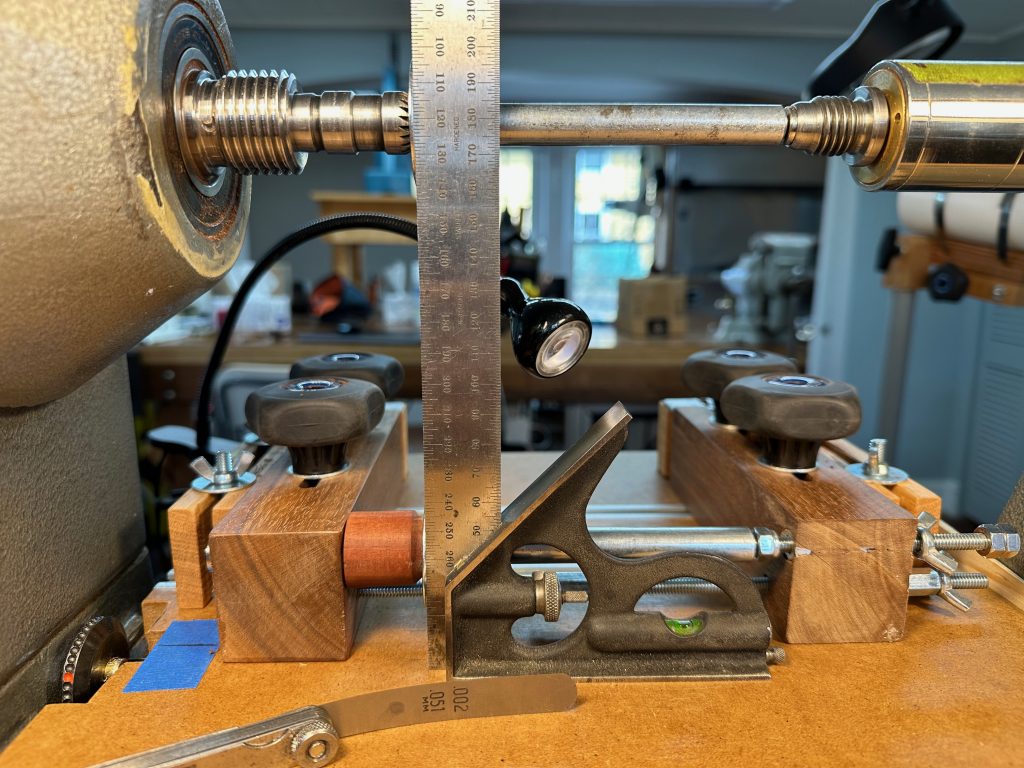

The pattern holder on the bottom has to be precisely aligned with the lathe spindle. A screw on the edge of the table allows for precise positioning along the length of the lathe bed. The center supports were moved in and out by screws until a piece of aluminum foil wouldn’t fit between the square and either alignment bar.

The pattern followers on the bottom of the tool holders were aligned with the top cutters by bringing their tips against the alignment bars and moving the top tool in or out.

This shot looking straight down on the top cutter shows a small gap that has to be eliminated.

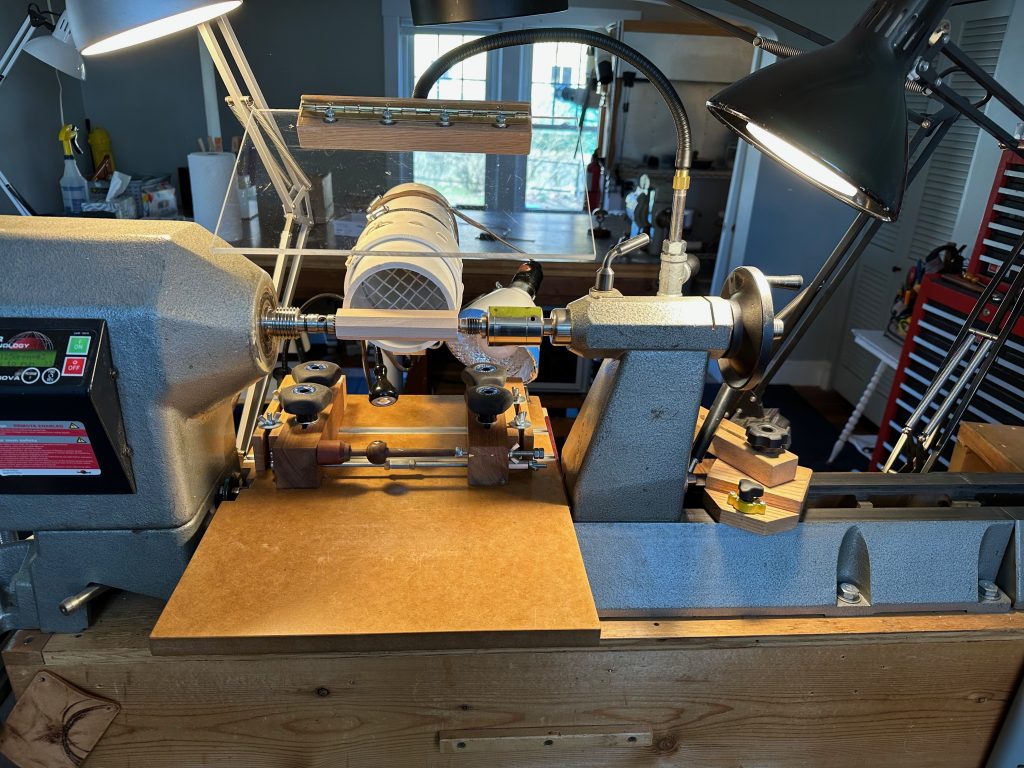

Once the table and tooling are aligned, it’s straightforward to use the pattern as a guide to cut a piece.

The bead and undercut were made by scrapers held in a special tool holder that slides along guides.

This photo was taken before I added stops and guide rails to better control the tool position.

The round tops were finished with scrapers and by sanding.

I made a tool rest holder that clamped to the table so I could use conventional turning tools with the table installed.

I cut flat sides on the heads with my table saw.

I used a fixture to hold the peg against a sanding disk on my lathe to set the overall angle of the head before doing the final shaping by hand.